1.0

Scope and Purpose

This

document outlines the general approach undertaken to identify, assess and

evaluate the chemical reaction hazards associated with chemical processes. It

should be noted that this document is not intended to be a standard operating

procedure, but an outline of the generalized working principles and

documentation of the rationale used.

This guideline is directed to

those personnel involved in research & development, process hazards

analysis (Process safety lab), kilo lab and commercial plant operations. It is

also useful to those involved in process hazard analysis and process safety

management.

2.0

Objective

·

increase

awareness of potential chemical reaction hazards associated with chemical

manufacture in batch and semi-batch processes

·

help in the

assessment of risks from chemical reactions, and advise on how to prevent and

control these risks

·

provide a

systematic approach for the design, operation and control of chemical reactions

in batch and semi-batch processes

·

advise on

safe management procedures and appropriate precautions to prevent or reduce

injuries and damage caused to property or the environment associated with

chemical manufacture; and

·

advise on

maintenance, training and information needs to prevent and control chemical

reaction hazards

3.0

Definition of terms

Activation energy: the constant Ea

in the exponential part of the Arrhenius equation associated with the minimum

energy difference between the reactants and an activated complex (transition

state), which has a structure intermediate to those of the reactants and the

products, or with the minimum collision energy between molecules that is

required to enable a reaction to take place; it is a constant that defines the

effect of temperature on reaction rate.

Adiabatic: a system condition in which no heat is

exchanged between the system and its surroundings; in practice, near adiabatic

conditions are reached through good insulation.

Adiabatic induction time: the delay time

to an event (spontaneous ignition, explosion, etc.) under adiabatic conditions

starting at operating conditions.

Adiabatic temperature rise: maximum

temperature increase (readily calculated, that can be achieved) which would occur

only when the substance or reaction mixture decomposes completely under

adiabatic conditions.

Apparent activation energy: the constant Ea

that defines the effect of temperature on the global reaction rate.

Autocatalytic reaction: reaction in

which the rate is increased by the presence of one or more of its intermediates

and/or products.

Batch reactor: reactor in which all reactants

and solvents are introduced prior to setting the operating conditions (e.g.,

temperature and pressure).

Decomposition energy: the maximum

amount of energy which can be released upon decomposition.

Decomposition temperature: temperature at

which decomposition of a substance occurs in a designated system; it depends

not only on the identity of the substance but also on the rate of heat gain or

loss in the system.

Deflagration: a release of energy caused by a rapid

chemical reaction in which the reaction front propagates by thermal energy

transfer at subsonic speed

Detonation: a release of energy caused by an extremely

rapid chemical reaction of a substance in which the reaction front propagates

by a shock wave at supersonic speed.

Endothermic reaction: a reaction is

endothermic if energy is absorbed; the enthalpy change for an endothermic

reaction is a positive value.

Enthalpy of reaction: the net

difference in the enthalpies of formation of all of the products and the

enthalpies of all of the reactants; heat is released if the net difference is

negative.

Exothermic reaction: a reaction is

exothermic if energy is released; the enthalpy change for an exothermic

reaction is a negative value.

Hazard: a chemical or physical condition that

has the potential for causing harm or damage to people, property, or the

environment.

Isothermal: a system condition in which the

temperature remains constant; this implies that heat internally generated or

absorbed is quickly compensated for by sufficient heat exchange with the

surroundings of the system.

Onset temperature: temperature at which a

detectable temperature increase is first observed due to a chemical reaction;

it depends entirely on the detection sensitivity of the specific instrument

involved; scale-up of onset temperatures and application of rules-of-thumb

concerning onset temperatures are subject to many errors.

Phi-factor: a correction factor which is based on

the ratio of the total heat capacity of a vessel and contents to the heat

capacity of the contents; the Phi-factor approaches one for large vessels.

Quenching: Abruptly stopping a reaction by severe

cooling or by catalyst inactivation in a very short time period; used to stop

continuing reactions in a process thus preventing further decomposition or

runaway.

Rate of reaction: technically, the rate at which

conversion of the reactants takes place; the rate of reaction is a function of

the concentrations and the reaction rate constant; in practical terms, it is an

ambiguous expression that can describe the rate of disappearance of reactants,

the rate of production of products, the rate of change of concentration of a

component, or the rate of change of mass of a component.

Runaway: a thermally unstable reaction system

which shows an accelerating increase of temperature and reaction rate which may

result in an explosion.

Time to maximum reaction rate: the measured time

to the maximum reaction rate during a runaway or rapid decomposition; the

specific result is highly contingent on the test method used.

Venting: an emergency flow of vessel contents

out of the vessel thus reducing the pressure and avoiding destruction of the

unit from over-pressuring; the vent flow can be single or multiphase, each of

which results in different flow and pressure characteristics.

1.0

Introduction

Any chemical process

will involve chemicals and its interactions and equipment in which it is processed.

This interaction of chemical within equipment possess some degree of hazard

which needs to be understood to control or eliminate the risk. Hence it is

important to understand what the parameters which determines safe chemical

process are and what are chemical reaction hazards.

4.1

Parameters

that determines the design of the safe chemical processes

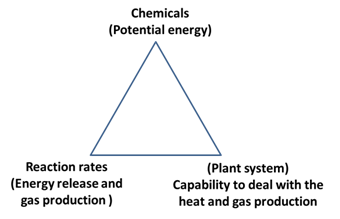

Three parameters that

is chemicals (its intrinsic properties), Reactions rates (Kinetics) and

Hardware (equipment) determines the design of safe chemical process as depicted

below.

Fig 1: Parameters that determine safe chemical processes

· Potential energy of chemicals involved: Design of a safe process requires

an understanding of the inherent energy (exothermic release/endothermic

absorption) during chemical reactions. This information can come from the

literature, from thermochemical calculations, or from proper use of testing

equipment and procedures. The potential pressure that may be developed in the

process is also a very important design consideration.

· Rates of the reaction/ decompositions: this depends upon

temperature, pressure and concentration. Rates of reaction during the normal/

abnormal process conditions must be determined to design safer processes.

· Plant process equipment and

design:Any

heat that is generated by the reaction must be removed adequately, and any gas

production must be managed. The effects and requirements of scale-up (that is,

the relation between bench-scale and plant equipment) must be considered.

4.2

Chemical

Reaction Hazards

· Chemical Reaction Hazards are the hazards that result from uncontrolled chemical reactions.

· An uncontrolled chemical reaction can be

defined as one in which the heat generated by the reaction is greater than the

heat which can be removed to the surroundings (plant heat transfer systems)

This results in the temperature of the reaction mixture increasing, which results in an increase in the rate of reaction. This in turn leads

to a further increase in the rate of heat generation. When the

temperature reaches the boiling point (and/or) decomposition temperature,

pressure generation rate can exceed the venting capacities of the plant system

resulting in an explosion.

· Runaway

reactions can therefore start slowly but accelerate,

until finally it can result in an explosion.

Chemical Reaction Hazards are the result of 3 main parameters:

Ø The thermal instability of starting/raw materials,

reaction mixtures and products.

Ø Rapid exothermic reactions that raise the reaction

temperature to decomposition or violent boiling.

Ø Rapid gas evolution.

Fig 2: Overview of pathway of

Chemical Reaction Hazards

Note: It is the

pressure that results in a chemical reaction hazard incident and not the heat.

However, the uncontrolled heat leads to pressure generation by the above

scenarios.

hi

ReplyDelete